Posted on 12/11/2012

Porsche Engine Rev Limiting Systems Engine Rev Limiter systems started in the early Porsche 911’s as a mechanical sliding ignition rotor whose sole job was to cut power in the event of an engine RPM over-rev. A section of the ignition rotor would slide outwards driven by centrifugal force depending on the engines RPM speed and would eventually make contact with a ground terminal, shutting the engine off until the engine reached a safe RPM range. The simplicity of the past is now gone and replaced with an extremely accurate electronic control system. The rev limiter for the 9X6’s and 9X7’s utilize a fuel/ignition cut off system operated by the DME (Digital Motor Electronics) controller that engages when the engines RPM reaches a model specific maximum limit. In addition to the current rev-limiter controls, today the DME keeps a record of all engine over-revs. The over-rev capture capability should be checked during a PPI (Pre-Purchase Inspection) be ... read more

Posted on 10/26/2012

Historically, Porsche’s paint quality has always been world class. However, over time, your car’s paint is exposed to combinations of dust, dirt, tree sap, bird dropping, water, chemicals plus everything else in the air which can take a toll on the quality of the finish. Of course, the painted surface of any car must be cared for to maintain its outstanding finish. Unfortunately, not all Porsche owners keep up with the maintenance of the exterior finish. Reasons differ, but the most common is just not having the time to do it yourself. Today, there are many fixed location and mobile professional detailing services that cater to conscientious car owners that want to preserve their cars fine finish. When choosing a detail service business, it is best to get recommendations from someone you trust, your friends, your mechanic, a high quality paint shop or the local PCA (Porsche Club of America) chapter. It is also important to use companies that utilize methods and p ... read more

Posted on 8/26/2012

Porsche has always built cars with incredible performance, handling and braking. From the early days of the 356 to the modern Turbo S and everything in between, all provide balance and handling that makes every automobile manufacturer envious. Drive your Porsche into a corner fast and a completely different personality emerges – a magical personality that the engineers at Weissach make sure is within every Porsche, whether destined for your garage or a checkered flag at Le Mans. Of course, over time, and a lot of corners, suspension components wear and can even break. If you happen to notice an abrupt change in your Porsche’s handling characteristics, be sure to have the problem diagnosed immediately. Whenever a handling issue is experienced, the first thing to check is the tire air pressures. If a tire is deflating, it can cause the car’s handling to become very unresponsive, unstable and potentially create a dangerous situation. A tire with very low air pressur ... read more

Posted on 6/28/2012

Sometimes it becomes necessary to weld on the body or chassis of your Porsche. This would usually be part of a repair following an accident but could also be non accident related repairs or modifications that would require welding to be performed somewhere on the car. We are specifically concerned about using the different types of electric arc welding. These include Stick, MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding also known as Heliarc welding. All of these electric arc welding types use electrical energy (either A/C or D/C Voltage) to generate extreme heat at the localized spot where the weld is taking place. As part of the welding process, an earth connection (welder ground) is made near the welding site to isolate and collect this energy during the welding process; however, not all of the electrical energy will necessarily take this path. High frequency electrical energy can be introduced into the car’s grounding and wiring systems through th ... read more

Posted on 5/16/2012

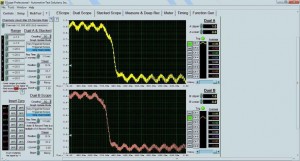

Recently we had a 996 Coupe in the shop, the customer’s concern was that the fuel consumption appeared excessive and the engine seemed to be less responsive than normal. We ran a complete controller interrogation, meaning we scanned all the control modules (computers) in the car for faults with the PIWIS (Porsche Integrated Workshop Information System) scan tool. Primarily we were searching for faults or fault codes in the DME (Digital Motor Electronics) controller AKA the ECU (Electronic Control Unit), there were no faults present. At this point most technicians would conclude that since there are no faults present, there must not be a problem, however, this is not always the case. Through experience we know and believe that the customer is usually very familiar with the operating characteristics of their car. With this in mind we continued our diagnosis. We performed a test on the pre-catalyst (before the catalytic converters) oxygen sensors utilizing a DSO ( ... read more