Posted on 6/6/2022

Porsche is a high-end sports car known for its powerful engines and outstanding performance. The last thing Porsche owners want to encounter on their journey is an underperforming engine. You invested a fortune to buy this car because you expect the highest level of handling and horsepower. You deserve to benefit the most from your investment with the help of dependable Porsche repair shops. Unfortunately, your car will eventually develop mechanical issues, such as poor engine performance. It's difficult to pinpoint a particular cause at first glance, so you'll need an auto repair technician who specializes in Porsche models to make a diagnosis and repair the issue. The best Porsche service specialist in Torrance, CA, is none other than our skilled and knowledgeable professionals at Callas Rennsport. We have a reliable garage for complete diagnosis and repair when your engine performs poorly. Now, let's take a closer l ... read more

Posted on 5/16/2012

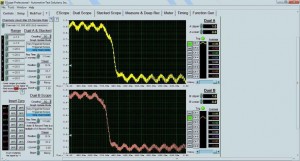

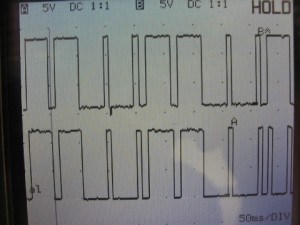

Recently we had a 996 Coupe in the shop, the customer’s concern was that the fuel consumption appeared excessive and the engine seemed to be less responsive than normal. We ran a complete controller interrogation, meaning we scanned all the control modules (computers) in the car for faults with the PIWIS (Porsche Integrated Workshop Information System) scan tool. Primarily we were searching for faults or fault codes in the DME (Digital Motor Electronics) controller AKA the ECU (Electronic Control Unit), there were no faults present. At this point most technicians would conclude that since there are no faults present, there must not be a problem, however, this is not always the case. Through experience we know and believe that the customer is usually very familiar with the operating characteristics of their car. With this in mind we continued our diagnosis. We performed a test on the pre-catalyst (before the catalytic converters) oxygen sensors utilizing a DSO ( ... read more

Posted on 12/29/2011

The history of Porsche diagnostic testers basically all started with the Bosch D-Jetronic fuel injection system tester for the 914 in the early 70’s. Then we received the 9268 digital output fault code reader in 1987 which would present the technician with an actual fault code number. The retrieved fault code corresponded to different conditions or problems recorded by the cars on board computer. The 9268 was intended to interface with the newly designed 16 valve 944S and 928 S4. This was eventually replaced by the 9288 nicknamed the Bosch Hammer because it was in the shape of a hammer, codenamed the PST-1 (Porsche Systems Tester-1) computerized diagnostic tester, circa 1989. The 9288 was mainly designed to interface with the 1989-on 964’s (911) and had to be capable of performing a “system adaptation” which was to reset all the controllers, much like a computer reboot. Later this procedure became known as a “vehicle handover”. Following the 9288 Hammer, Porsch ... read more

Posted on 5/25/2011

Porsche street cars first received computerized engine management for the 1980 model year. By today’s standards, the early version was elementary in comparison. This addition was obvious by the installation of an oxygen sensor to monitor oxygen content in the exhaust stream. This was Porsche’s approach to improve engine performance and tailpipe emissions in most operating conditions. In 1984 Porsche installed a full computerized engine management system named Digital Motor Electronics (DME) in the 911 Carrera. DME controlled not only the fuel injection but also the ignition system making it a complete package with one control unit for the entire engine management system. A basic description of the computerized engine management system is a control unit (computer), also known by some as the brain, which receives data from sensors on the engine that are monitoring its operation. These sensors monitor engine temperature, RPM or speed, throttle position, intake ... read more

Posted on 4/27/2011

The oxygen sensor was developed in the late 1960’s by the Robert Bosch Corporation. Porsche first installed an oxygen sensor, often referred to as an O2 sensor, in all their cars starting from 1980. The O2 sensor plays a critical role in the proper performance of the engine and helps support the effective operation of the emissions system. The O2 sensor is physically located in the engine’s exhaust system and monitors oxygen content in the exhaust gases exiting the engine. The O2 sensor operates by the principle of a chemical reaction that generates a voltage when oxygen in the exhaust gases comes in contact with the precious metals that comprise the O2 sensor. If little or no oxygen is present in the exhaust gases, a rich running condition exists and the voltage will build up higher in the O2 sensor. A lean running condition will have a lot of oxygen in the exhaust stream and this will generate a small amount of voltage. This voltage signal is sent to the Dig ... read more